Hy,

after some problem with electronics parts, I try now to scan a part.

I use 2 green line lasers, well calibrated (vertical, crossing in the center of the plate). The camera is well centered too.

Calibration takes place properly. I try to scan a simple cylinder.

The result is like nothing!

In the configuration file, I have a doubt about certain parameters:

"turnable": {

"Steps": 3200,

"Radius": 100,

"Height": 80,

"degree_per_step": {

"Low": 3.6,

"Medium": 1.8,

"High": 0.8

}

Can you help me ?

Now the fun and guessing begin. I don't know exactly what height dimension does so haven't changed from the 155 given in the example provided in the default.config.json file. Please check the calibration chart information as the one I have is 6 rows, 11 columns and 13 mm squares which I beleive is the standard one for the Ciclops. If used 10 columns as the example shows you can have problems. Find the page on the Fabscan web that shows how the columns and rows are determined. I advise using a simple cubic to test your adjustments and calibration. If you can get the 0 and 1 ply files to have good alignment then try a more complex.

For instance:

A tapered scale I think reveals that a laser or lasers or camera center may not be truly vertical.

Different sizes in the plan view probably indicate that one or both lasers does not indeed pass through the table center.

In this part of the process so much can be adjusted, I'm sure that I'm only a beginner myself.

I would do this initial study not scanning color (texture). Bloom or reflection will mess up what the camera sees and when you adjust the best trace the color scan is not good.

Incident light gives problems. There's a reason for the cover and inside black paint suggestion for the Fabscan. Do your scan in a dark room at night for the best conditions, also adjust the camera parameters-contrast, saturation, etc. for the finest detectable laser line.

Don't only read the information on the Fabscan website once but perhaps 2 o3 times and then refer back often because things will surely change. I strongly suggest Mario's book "Das 3D-SCANNER PRAXIXBUCH" as a reference. It does a very adequate job of explaining and giving procedures which I have found to be very helpful.

I'm busy responding to something else but will give information on how to make a screen with black cloth for an enclosure that may help with the Ciclops,, also the cubic I use for checking my set up.

Hy,

some news about my problems !

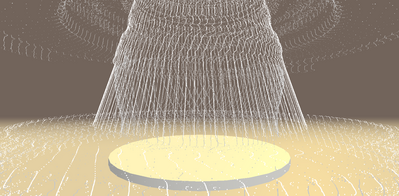

I made a closed box with a black interior around my cycle. The result is much better (scan_hibou.PNG).

But I still have some problems !

How to avoid having the lower trace, at the level of the turntable ?

I understood that the parameter turnable:height corresponded to the max height of the scan.

But nothing for the minimum height ?

Thanks for this solution.

I now have another problem. The 2 captured clouds are very slightly offset from each other.

I checked that the 2 lasers are vertical, that they intersect in the center of the board.

The camera is also well calibrated on the center of the set.

I used Cloud Compare to realign the 2 clouds, but that is not the solution.

What could be the problem?

the distance between each laser and the camera is the only thing I didn't think to check!

Yes I have a 3D printer.

I am very interested in your stl files and your method to guarantee me a good calibration.

Thanks in advance.

Hello, I think we need to clarify what I met to say. The distance between the plane of the camera trace for the same points on the object when scanned by laser0 and laser1 should be the same and if not show a likely error in camera centering or laser trace centering.

Here are zipped files of the calibration cone to aid in the calibration procedure and a test object which I use to grade the quality of my calibration. The calibration cone aids in setting the vertical to the table and bypasses any variance to motor mounting and flatness of your mounting plane and variances in camera support. You should be able to check the perpendicularity of the table plane to the motor axis with it and also check the perpendicularity of the lasers. I would also recheck the passing thru center of the lasers after removing the cone before running the calibration. Remember this is only an aid but no guarantee that you will do better. I think it improves your chances.

Of course, you should check the accuracy of the calibration cone part in particular to ensure that it printed correctly. Please correct my across corner dimension to 50mm for the cubic in the last communication. The spacing of the small hole in the base is spaced according to the FabscanPi table. I thread a 3mm flat head screw in the hole to aid in the location the of cone and cubic. For the actual scan it has been recommended that double sided tape be used to prevent object rotation during scanning. Depending upon the table used with your cyclops set up they may not fit.

OK. Thanks a lot. The printing of the 2 parts is in progress.

Can you explain to me how you use these 2 parts, and what should be the results obtained in terms of projection of the 2 lasers ?

Use of Calibration Cone and Test Cubic

The calibration cone is derived from what is used on the Sardauscan scanner. I find that it provides a better base to rest on the turntable and expect it perhaps to be more accurate than depending on the perpendicularity of a cemented-on calibration chart to a support. A well-adjusted 3D Printer should produce an accurate rendition of the cone, but I encourage checking with a drafting triangle and flat surface for perpendicular accuracy.

Actual setup procedure is consistent with what you would normally do as advised on the FabscanPI web site. The turntable center must be determined and marked preferably with crossed lines. Place the cone face on a line and centered. Set the vertical green line of the camera in the browser window on the center. The camera may have to be translated and rotated to get it in line vertical. Check to verify that it passes over the turntable center without the cone in place. Then I would put the cone back in place on each of the four quadrants to be sure it is consistently vertical in each place as I think any difference indicates an error in turntable center mark or turntable plane not perpendicular to the motor axis. This is possible but not too likely to occur with the FabscanPi design. The browser refresh rate is slow so this will take some time. Any inconsistency should be corrected before you continue.

After all of this, with well-focused lasers go ahead and adjust to give vertical lines centered on the turntable and cone vertical. Again, a check of passing over the turntable center without the cone in place is justified.

Now run your calibration.

At this point with a successful calibration, i would expect a perfect rendition of the test cubic for a perfect setup of the camera trace and lasers. Perfection is often difficult, so I use the test cubic to judge how well I have done and if not satisfied with the result, do the procedure again.

After you are satisfied with the test scan results, go ahead and try scanning an object of your choice. I have not used the version 10 software enough that I care to advise as to the settings for scanning as there are many setting selections available. See what is available on the Forum. As I have mentioned before Mario's book "DAS 3D-SCANNER PRAXISBUCH" gives a very comprehensive explanation of the scanning process and items to be considered, the handling of the .ply files and the rendition of the mesh with the available software. Unfortunately, as I don't know the German language, I have had to depend upon Google Translate which does a very creditable job.

Good luck.