Hi @mario ,

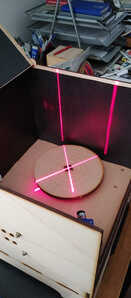

after a 3-years long stop I started again fighting against my FabscanPi. Before COVID-19 pandemic, I added a second laser to my original setup (the base setup I bought from Wetterott Electronic); the only things that are different is the second laser (since I ordered a fixed focus red laser, but I received a focussable red laser module) and the led ring camera mount that I mounted using four springs in order to better center the camera (you can see the whole setup in the pictures, including the 3D printed laser towers and the black walls). I run the latest pre-built image on a Raspberry Pi 3B+, setting up the main clock at the standard frequency of 1400MHz (I added a small passive cooler to the CPU and I will add two small fans to cool both boards and the NEMA 17MH3410 stepper motor), and I power up the scanner using two separated PSU (a 5V PSU for the Raspberry Pi 3B+ and a 12V PSU for the FabScanPi HAT).

I was in this situation three years ago (with just the second laser)... now, with 0.10.0 and the latest firmware available, scan quality is decreased and even setting up the highest scan resolution the point cloud is very sparse and with low deteils (using a single laser and the 0.7.0 release I got better results three years ago...).

I tryed to perform a good calibration, trying to cross lasers as precisely as I could in the center of the plate, trying to better positioning the center of the camera, and verifying the height of the top of the plate (I measured 245mm and not 155mm as in the default configuration file, but checking the position of the mounting ring I found it is 5mm below the top of the NEMA 17MH3410 axis... as requested in mounting instructions).

Despite all I told above, my scans are unusable, dirty and completely deformed (and i fixed the scanned piece to the plate in order to avoid underided movements).

Please help me!!!

Thanks,

Iade Gesso, PhD (in Computer Science)

Do you have changed to 2 lasers in the default configuration file?

Hi,

have you tried to perform a scan with just one laser to be sure that the basic software setup is working. Does your motor run in 1/16 step mode. If you are using the FabScanPi HAT, double check which motor driver you are using. Depending on your driver you might need to change some jumper settings on the HAT.

https://fabscanpi-server.readthedocs.io/en/latest/steps_fabscanpi.html#assemble-motor-drivers

Another important configuration parameter is number of steps. It depends on the motor/driver setup. For a motor with 200 steps per full rotation in 1/16 mode the value should be 3200. Some kits came with a 400 steps per rotation motor, those should be set to 6400 steps in the configuration.

Related to "shadows": try to prevent a light incidence. Try to cover the slits on the lit. Maybe it is easier to cover the whole case with some fabric for a quick test.

Keep in mind that you need to do a re-calibration after changing the laser config settings.

- Mario

Hi @mario,

first of all, thanks and a small errata corrige...

NEMA 17MH3410 stepper motor

but yesterday I was a bit fused and the correct stepper motor model is NEMA 17HM3410.

Another important configuration parameter is number of steps. It depends on the motor/driver setup. For a motor with 200 steps per full rotation in 1/16 mode the value should be 3200. Some kits came with a 400 steps per rotation motor, those should be set to 6400 steps in the configuration.

I'm sure it's a 400 step motor because if in the default.config.json I didn't change from 3200 steps to 6400 steps, I wasn't able to perform calibration.

have you tried to perform a scan with just one laser to be sure that the basic software setup is working

Three years ago I was on the 0.7.0 server version with a single laser and the scan result was not exciting but the point cloud was infinitely more precise and dense... Yesterday I tryed to disable the second laser setting up the number of lasers to 1 in the default.config.json but calibration failed... Do you think it's better to unwire the second laser unit?

Does your motor run in 1/16 step mode. If you are using the FabScanPi HAT, double check which motor driver you are using. Depending on your driver you might need to change some jumper settings on the HAT.

I have to check this... this afternoon I will look for it. But if with older server version it worked, I think the motor driver was configured correctly. Where I can find the jumpers you mentioned?

Many thanks,

Iade

PS: at the moment, the only point through which the light came inside the chamber is the joint of the lid which does not fit well on the hinge side.

Related to "shadows": try to prevent a light incidence. Try to cover the slits on the lit. Maybe it is easier to cover the whole case with some fabric for a quick test.

In my case it seems part of the shadow came from erroneous detections of the laser on the plate and on the wall

I have to check this... this afternoon I will look for it. But if with older server version it worked, I think the motor driver was configured correctly

Ok @mario, I checked the motor driver is a TMC2100-LA, the black PCB version... so I think it is the model that handle 3-5V.

The motor should be set to the correct current level, otherwise the motor will overheat, loss steps or even wobble. A good starting value for VRef is ~0.7V. You can find detailed instructions at Watterotts F.A.Q.

What I never did is to setup motor current (but three years ago I didn't see the above note in the documentation...). I need to do this?

Still looks like bad calibration values to me.

There is no need to do any jumper settings while using a TMC 2100. But i recommend to set the current of the driver. A voltage of 0.7v at the reference pin should be fine. When the driver gets to hot it skips steps this will result in bad scan results and more evil a bad calibration.

Hi @mario ,

today I added a couple of passive heatsinks to the TMC2100 (the second one is just to enlarge the hot area coverage, even if I put the former exactly in correspondence of the mai driver integrated circuit).

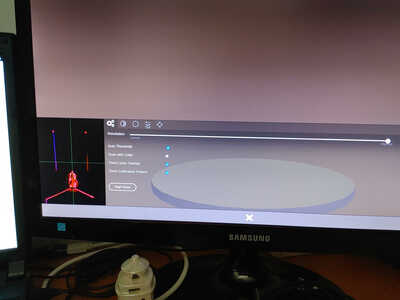

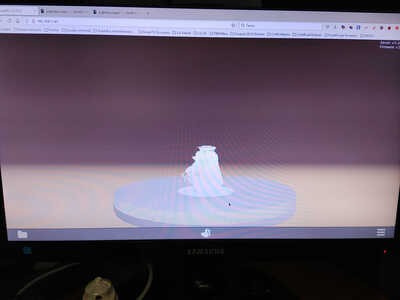

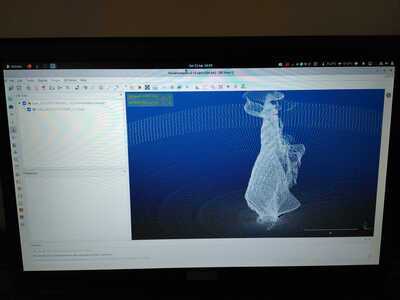

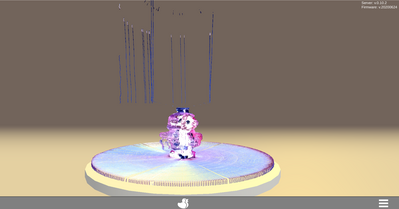

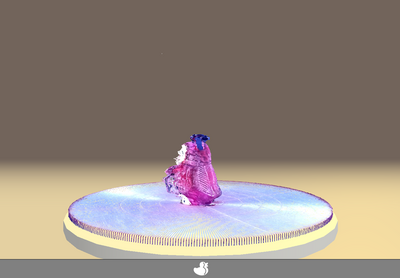

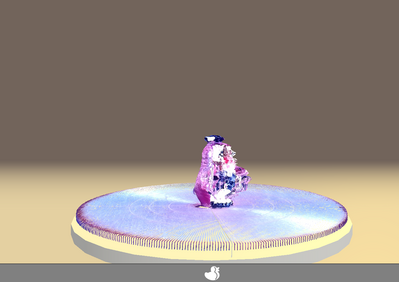

Then I recalibrated the scanner from scratch (using a default.config.json file without any previeous calibration data). The results seems to be better than the previous ones but, considering that the scan process was set to high resolution, the result is still quietly poor (I will try adding active cooling in next weeks); you can see the scan results here:

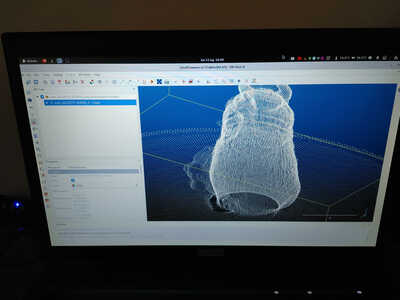

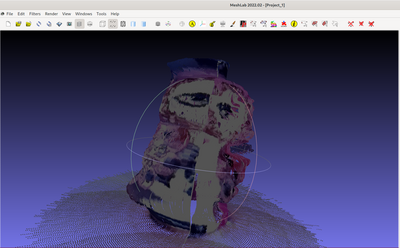

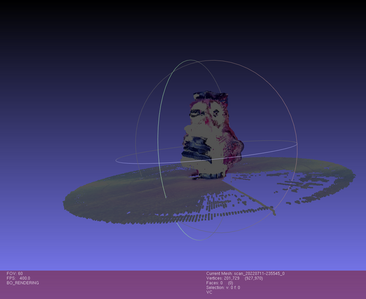

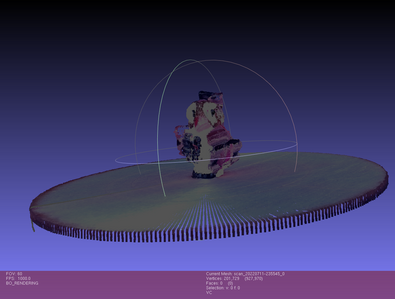

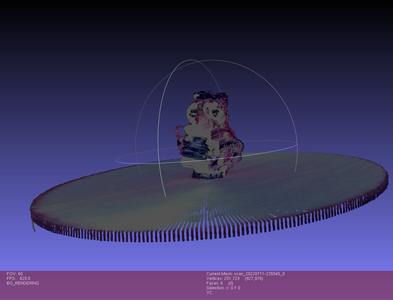

Moreover, in the following you can see the point clouds as MeshLab shows to me:

- "Laser 1"-only point cloud:

- "Laser 2"-only point cloud:

- Merged point clouds:

Iade

PS: I was thinking about the fact that the object can vibrate during the rotation of the scanning plate ... do you think it can affect the quality of the acquisition? How do you suggest "to glue" the object to the plate?

correspondence of the mai driver integrated circuit

"correspondence of the mai driver integrated circuit" was a typing error... the right text is "correspondence of the main integrated circuit of the stepper driver"

Thanks,

Iade